What is Printed Circuit Board?

Printed Circuit Boardalso known as PCB, is an enclosed board which you can find in many devices like radio, radar, pagers & computers. There are many interconnection of electrical & electronic components in the board. These PCBs are made up of different types of materials mainly composite epoxy, fiberglass or any other

Mostly the designs of the PCBS for day to day electronics consists of only a single layer. But, for hardware like motherboards or graphic cards used in computers may have multiple layers, which might reach up to 12 layers or so. This PCBs are also used in many other different fields apart from computers & consumer electronics, which includes the below:

- Aerospace & Automotive industries:

Both of these industries use the flexible PCBs, & they are specially designed to handle higher frequency environment. They are also quite light weighted, though completely depends on the design & specifications. The PCBs also match to the tight spaces found in these applications like behind the instrument gauge or inside the instrument panels.

- Medical Equipment:

The PCBs used for medical equipment are generally very high in terms of the density, & this can be used to create the minute & the most complex designs also. This thing helps in smooth working of the devices that are light in weight & size is small. You can now find PCBs in all the devices, be it a small pacemaker or a huge device say, the CAT scan machines or the X-ray machine.

- Lighting:

The LED lights are quite popular these days as they are highly efficient plus they consume less power. But ever thought why can be this possible? The aluminium-backed PCBs are used for the same. An aluminium backed PCBs help in heat transfer at high levels in compared to a standard PCB. They are also used for lightings & high-lumen LED lights.

Generally, in a PCB assembly,the components of a PCB are electrically connected by two different methods- hole technology & surface mount. In a surface mount technology, the J-shaped or L-shaped terminals of each of the components are contacted with the PCB, where, in the hole technology, every component has thin leads which are pressed with the help of tiny holes, followed by the soldering process, the connection boards are soldered on the other side.

Different types of PCBs

So, in short there are several types of PCBs with different types of materials used, different usages, & the designs are specific depending upon the requirements of the device. And, so you need some special tools to meet the exact requirements of the device. Let’s get into a depth to know the types of PCBs:

- Single-Sided PCBs

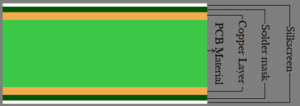

This type of PCB is the most regular one. Going with the name, here the circuit board contains a single layer of base substrate or material. It is nicely layered with a thin metal. The material which supports electricity power can be used here for e.g. copper. On the top layer of copper coating, a protective solder mask is applied with a coating of silk screen. The silk screen coating is done mainly to mark the main elements on the board. The single-sided PCBs has many advantages-

- a) The designing & manufacturing is very easy;

- b) At the time of large volume, this PCBs can be used, & the cost will be comparatively less;

- c) And the PCBs can be used for simple circuit boards like calculators, sensors, cameras, relays, power sensors & electronic toys;

- Double-Sided PCBs

For the Double-sided PCBs, the substrate is layered with a metal coating on both sides, & the elements are also attached to both the sides. With the help of tiny holes, the metal parts are joined to each other. To connect one side of the PCB to the other, hole technology &surface-mount technology is mainly used. In the Surface Mount Technology, the electrical components are placed directly on the surface of the circuit boards, which helps to complete many number of circuits with less usage of space, with improving the functioning of the board, increases the speed & reduces the weight. Whereas, in the hole technology the lead components are inserted in the drilled holes on the circuit board & the ends are soldered to the relevant component.

This type of PCBs is used mainly in those devices that need a higher level of circuit complexity for example, LED lighting, Amplifiers, Vending machines, instrumentation, power supplies & HVAC systems.

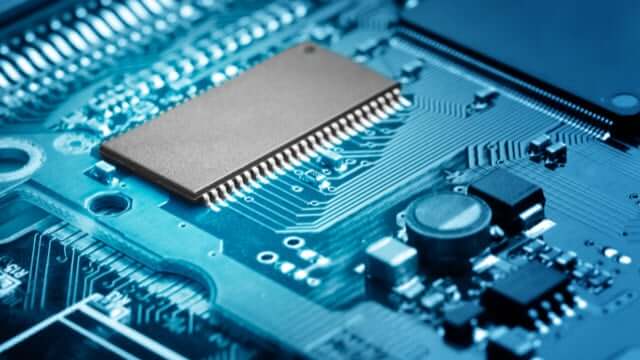

- Multi-Layer PCB

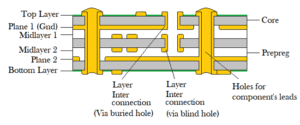

Any PCB that has more than two layers is known as the Multilayer PCB. So, very easy to understand, that in this PCB, you will find three layers of copper mainly. The technology used in the double sided PCBs is further expanded here. Many different layers of insulating materials & substrate helps in separating the layers in this type of PCBs. A good layer of glue is applied in between the insulation layers, this makes sure that no damage will be caused to any component of the circuit in case of excess heat. The usage of the extra layers is known as power planes. Generally, these PCBs are compact, & weigh light & space used is less. To consume less space & keep the circuit compact, this type of PCBs is used for complicated electrical devices like satellite system, medical devices, GPS technology, filer server & data storage.

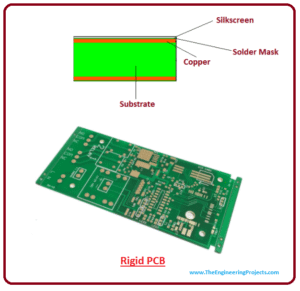

- Rigid PCBs

Many printed circuit boards are inflexible & are formed using a solid substrate material, & hence cannot be bent or twisted. This type of circuits is majorly used in motherboard. The Rigid PCBs are very solid & rigid substrate like fiberglass is used which restrains the board from twisting. The layers of the PCB can vary from single layer to ten to twelve multi layered PCB. The biggest advantage of this type of PCBs is repairing & maintenance can be very easy as the components are marked well, & the signal paths are also organised well. Secondly, since the PCB is relatively compact, you can easily create different variety of circuitry around it.

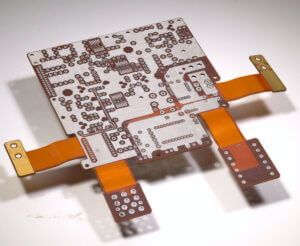

- Flexible PCBs

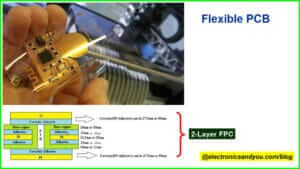

As the name suggests, the PCBs that can be bent or twisted are known as the flexible PCBs. These PCBs are constructed on a flexible material like a flexible board or a flexible plastic. Though the cost of this kind of PCBs is high comparatively & they come in single, double or multilayer form. But the biggest advantage of the flexible PCBs is that they are flexible & can be turned & twisted from the corners also, & this might help to save the cost & the space, as the single PCB can be turned & twisted to cover areas which might be covered by the multiple rigid PCBs.

Flexible PCBs are quite environmental friendly, & so can be used in hazardous conditions also. As the materials used to build the PCBs are corrosion resistant, waterproof, shockproof, & can bear high temperature.

- Rigid-Flex PCBs

The combination of flexible & rigid PCBs is the Rigid-Flex PCBs. Here the multiple layers of Flex PCBs are connected the many rigid PCBs layers. There are many advantages of Flex-rigid PCBs for many applications like cell phones, digital cameras, pacemakers, & automobiles. This type of PCBs is also best suited under harsh climatic conditions. There are many benefits – it is light weight & saves 60% of the space, & this PCB is very accurate & best suited for military & medical related applications.

It can be very right to say that the demand for the PCBs is increasing in all of the industrial sectors. With the passing years, the design of the PCB is developed from single layered PCBs used in the simple devices like calculators & remotes to the most complicated ones that needs to be accustomed with hazardous environmental conditions. The PCB manufacturersput their best efforts in catering the competitive markets of the devices.

Recent Comments