I and my team would like to thank you for your outstanding service and excellent quality. I got my first PCB from you which looked great. When I had queries, your staff was polite in answering and was in touch with me on regular basis regarding my needs before purchasing the boards. When I got the boards they looked clean and well manufactured. I just want to thank you for your high-quality service and products and I will certainly share details about your company with my contacts.

To many industries and for all purposes, we provide cable harness assembly and wire harness fabrication services. By meeting the demands of various customers for customized cables or wiring, Jayshree Instruments takes pleasure in its achievements. By offering cutting-edge solutions to contemporary problems, our years of expertise help us to stand out among other manufacturers.

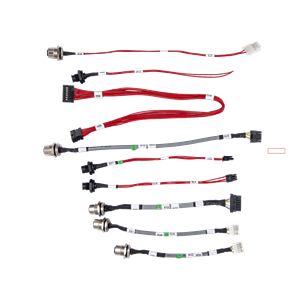

Custom cable and custom wiring harness assembly highlights

- Decades of expertise in wire harness and cabling solutions.

- Statutory certifications as well as industry-specific quality systems.

- Quick transition from NPI (New Product Introduction) to large-scale manufacturing.

- World-class training methods and procedures.

- Supply chain integration partnerships.

- Decreased shipping costs and competitive cost benefits.

- Engineering highlights

Engineering highlights:

- Engineering design recommendations aimed at Quality, Cost and Delivery efficiencies

- Technology advancements

- Validation of documentation

- Cross-referencing of components and available other sources

- Reverse engineering custom cable assembly and customized cable

- Rapid prototyping

- Concurrent Engineering

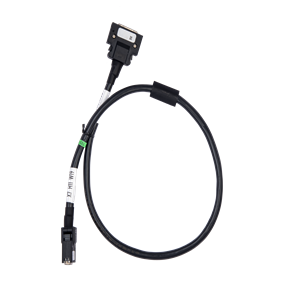

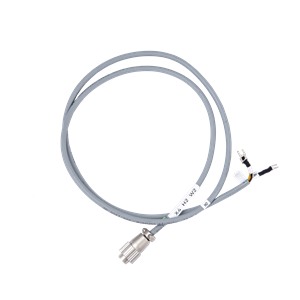

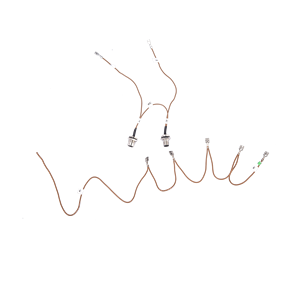

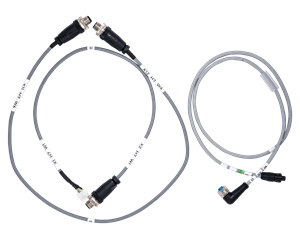

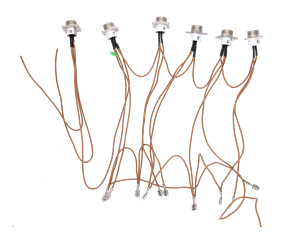

Product Gallery

Why Choose Us

One stop fabrication and assembly.

Parts sourcing

Comprehensive quality assurance

Professional engineering team

High efficiency with competitive price ranges

Get A Quote Now

For several years, we have had a great business partnership with Jayshree Instruments and are extremely pleased with the quality of the products they manufacture for us. The PCB and cables we ordered were fine, and they all worked well. They have proven to be a valuable partner and we are very impressed by their technical team, who are very professional and supportive. Jayshree Instruments is a proactive and attentive partner who is dedicated to providing dates and delivering them entirely on time. We highly recommend this company for collaboration as a fantastic business partner.

Epic Energy Ltd

One of the few firms that can do both mechanical and electronic design work and manufacture the finished product is Jayshree Instruments. They will finish off the design from basic necessity to circuit design and come back with a validated product ready to use. What we admire the most about Jayshree Instruments is this capacity to do both design and development. They're both very welcoming and nice individuals to work with.

3devo

What is cable assembly?

A group of cables are bundled together and protected by a robust external product. Typically, they are constructed from strong materials like vinyl, shrink-wrapped thermoplastic, or thermoplastic rubber. The purpose of a cable harness assembly is to send electrical power or messages. A wide selection of cable and wire-loom assembly services are provided by Jayshree Instruments. We provide a wide range of sectors with custom cable harness solutions, including the defense, automotive, mining, medical, telecommunications, and general electronics. We offer “End to End” solutions using the most up-to-date production machinery, integrating Wiring, PCB Assemblies, Box Build, and Testing. If needed, we can provide in either low or high volume with a speedy response.

Our customized cable assemblies can meet the challenge of needed parameters, whether they are created with unique client needs or for a special purpose.

Jayshree Instruments has the design capability and practical experience to build cable assembly that require any number of connectors, styles of termination or types of cable. As one of the best wire harness manufacturing company in Gujarat, Jayshree Instruments helps manufacture custom wire harness. Our team is very qualified and experienced to satisfy all kinds of custom cable assembly and wire harness requirements.

Industries we serve

CABLE ASSEMBLIES FOR MEDICAL INDUSTRY

With years of experience, Jayshree Instruments makes custom cable assemblies for numerous medical devices and equipment. We offer all that you need, be it safety jacks, bio-sensitive connectors, cable connectors for medical applications and more. Our team has the experience and have the tools and a dedicated process to create the cable assemblies you require.

CABLE ASSEMBLIES OF TELECOM

Demand for wireless technology is consistently increasing and the telecom industry is quite wired. But Jayshree instruments provides all the capabilities to create the cable assemblies and connectors you require. Our design team will make sure you get the cable assembly; be it cable for 10 conductors, a coaxial cable, over molds for USB’s and more.

CABLE ASSEMBLIES FOR MILITARY APPLICATIONS

Cable assemblies used in Military applications are generally used in harsh situations. Jayshree Instruments has experience in creating cable assemblies for military applications for a very long time and can help you create strain relief cables and over mold connectors to survive in tough conditions. We can help you make custom cable assemblies to satisfy your complicated requirements as well.

CABLE ASSEMBLIES FOR INDUSTRIAL CONTROLS

For all your industrial control needs, Jayshree Instruments will help you create cable assemblies with strain relief cables, cable stops and over molded connectors to confirm hermetic sealing.

CUSTOM CABLE ASSEMBLY FEATURES

Jayshree Instruments offer custom cable assembly design expertise. We have manufactured cable assemblies to fit a vast field of flexural requirements. Our experience and abilities help us efficiently create custom cable assembly for a variety of industries.

CONDUCTOR SIZES

We can eject conductors of different gauge sizes and also can combine different sized gauge to create a mixed gauge cable. The sizes are available ranging between 34 awg to 12 awg.

CONDUCTOR COLORS

Jayshree Instruments is a well-known cable assembly manufacturer and we can make cable with numerous conductors. Especially to keep a track of conductors we can make use of different colors, different stripes, text, dashes and more to make sure the right conductor is used for the right spot.

STRANDING SIZES

Conductors can be made with stranding which is as small as 0.0002 inches, which is great for hi-flex and supply cables. Stranding can be of different materials like care copper, tinned stranding, tinned conductor and more. They can also be make of metals like silver to get better conductivity

CONDUCTOR INSULATION

Conductor insulation is the first protection layer in any cable for which we use a wide range of insulations from basic PVC, PE or PP. The stiffness and softness of each material may differ

FILLERS

To make a cable give the best results, it is important to include fillers in the electric cable. Materials like basic cotton, nylon and Kevlar are used usually. All materials are custom matched as per the requirement of the application to give the best outcome.

WRAPS AND SHIELDS

A cable’s conductor needs to be wrapped or shielded generally. High flex cables require a soft barrier between the conductors and outer jacket to avoid abrasion. Numerous electric cables require shielding to secure it from RFI or EMI interference. Materials like fleece, cotton and aluminized Mylar are used to help the cable match the operating environment. It is usually wrapped with spiral overwrap.

JACKET MATERIALS

The final barrier between the environment and the inside of the electric cable is usually its jacket. The final covering is used like an insulator, a shield and protective cover. To create a cable we can utilize materials like PVC or natural rubber, Teflon or Silicone.

PROCESS OF CABLE ASSEMBLY

The cable assembly process is tricky, time consuming and task oriented. Below is the process of cable harness assembly:

STEP 1: Design

Cable harness conducts power and transmits information in a uniform way. Engineers and designers must explain and overcome electrical issues regularly, especially during the electronic product research and development stage to bring a product to the market successfully.

One of the most important part of this includes a challenge which has a custom design for each products electronic part and step by step cable harness manufacturing procedure to finish the assembly. In this step, designers select harness components and decide on other use specifications.

STEP 2: Prototyping

Prototyping allows an engineer or designer to see the final product in real. This is to test the harness in the actual application before implementing the first production run, assuring the best performance.

STEP 3: Production and Assembly

In wire harness manufacturing, design specification must be accomplished along with high quality standards. Cable harness manufacturing process still does rely on manual assembly even after the global expansion of automated manufacturing. Hand manufacturing of harness and cable assemblies is necessary because of the minute and time consuming steps which help to complete the process. Though needful automation can be incorporated in the process.

One more reason behind the manual production of wire harness and cable assemblies is that it needs to be customized for each application. It has particular components designed for specific larger parts. This step includes wire cutting, stripping and connecting and then ends at assembly.

Wire cutting is to be done in the right length which can be executed by a wire-cutting machine. The next step needs the wire ends to be stripped for the cores to be exposed. This step is initiated to attach terminals or connector housings or modules. And then lastly the wires are gathered in a harness using an assembly board to fulfill the design specifications.

STEP 4: Testing

After the process of production, each wire harness compulsorily has to undergo electrical safety testing for any kind of specifications it be face in real. This is an important step to ensure the final product performance to be 100% secure.

For more information about the cable assembly, we offer at Jayshree Instruments, call us today at +91 79 2657 8740 / +91 84609 59733 or fill out our quote form.

Different TYPES OF WIRE HARNESS TERMINALS

Wire Terminals are available in a variety of shapes and sizes. This depends on the size of wire and screw. Here several types of terminals are used for Wire Harness Manufacturing.

RING TERMINALS

A ring terminal has a round-end helping a screw or stud to be attached. They are also commonly known as ring connectors which are available in various sizes. It is necessary that the ring terminal is compatible with the wire gauge and the size of stud. They are usually soldered or crimped to the wire and are available insulated or non-insulated.

SPADE TERMINALS

Due to the shape of the terminal, Spade terminals are also commonly known as spade connectors or fork terminals. It is available in various sizes depending on the gauge of the wire and size of the stud. For efficient attachment and screw removal, the open-ended spade terminal is very useful and more importantly for wire harness projects where the space is a concern for installation. Spade terminals are available in insulated as well as non-insulated.

HOOK TERMINALS

Hook terminals are similar to spade terminals which are convenient to use with an open end. They are available in insulated as well as non-insulated. They provide a simple yet durable connection for different kinds of projects.

QUICK-DISCONNECT TERMINALS

A quick-disconnect terminal offers an easy connect and disconnect with two wires along with convenient and reliable usage. They are usually used in consumer products, auto products and other industrial products. The products using quick-disconnect can be insulated and as well non-insulated. This terminal assures stable and durable connection.

BULLET TERMINALS

Bullet terminals assure an easy, secure and reliable connection. It is easy to disconnect as well. They also connect to the open-ended female connectors as well as male connectors providing a high-quality connection. Which is why connection with bullet terminals helps avoiding corrosion and other harmful materials to get in the wire harness.

BUTT TERMINALS

A Butt Terminals terminates or connects single or multiple wires. They help avoid abrasion and cutting. They offer extra protection to keep the moisture, corrosion and other negative elements away. You just need to install each wire on the open end of the connector, and then crimp the terminal from both the ends to secure the connection.

FERRULE TERMINALS

Ferrule terminals are utilized in numerous applications for fastening, sealing, joining or reinforcing wires to each other.

FLAGGED TERMINALS

Flagged terminals are also known as Flag connectors ensuring secure and convenient connection. They work well in tight spaces and also when a quick-disconnect is too large. Flagged terminals assure easy connection and disconnection

Wires are available in different types as well like stranded, flexible ground braid, ribbon cable – Gray, THHN – solid, THHN – stranded. These wires are used as per certain specifications

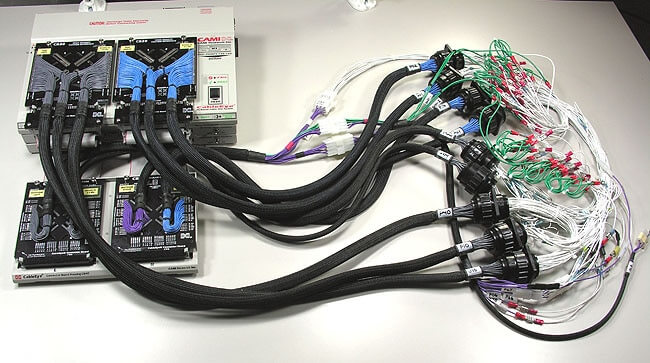

Testing of Harness

Looking for Wire Harness Testing Equipment manufacturers? Jayshree Instruments is the one stop solution for everything related to electronic manufacturing services. We have been manufacturing a variety of Wire Harness Testing Equipment from the latest technology as we believe in quality manufacturing for our clients.

One of our main methods for Harness testing is Automatic Test Equipment. An ATE is a simple digital multimeter controlled by a computer containing dozens of complicated test instruments which is capable of automatically testing and finding faults in sophisticated electronic packaged parts or on wafer testing which includes systems on chips and integrated circuits.

DIFFERENCE BETWEEN CABLE ASSEMBLY AND WIRE HARNESS ASSEMBLY

DIFFERENCE BETWEEN A WIRE AND A CABLE

A wire is a materialistic strand that conducts electricity. For example, aluminum and copper. And a cable has a group of wires that run together. They are usually bonded or braided together which is why they appear like bunches or intertwined wires.

WHAT IS A WIRE HARNESS?

A wire harness is a group of cables or wires that employs inexpensive components to keep the parts connected in a neat and effective way. The interior wires and cables of a wire harness are often covered with a thermoplastic-like sheath material for protection. However, the majority of the time these components come with their own personal protective sheathing, which eliminates the need for further protective measures.

Geometric constraints and electrical needs are the two basic challenges that a wiring harness addresses in an electrical system. There are several uses for wire harnesses in electrical wiring for both business and residential buildings and airplane engines.

WHAT IS A CABLE ASSEMBLY?

Cable assembly is a group of cables or wires which are covered by an intensive exterior product. They are usually made of heavy materials. Their functionality is similar to wire harnesses, including keeping cables and wires in place. But they are designed for entirely different environments. They are specially designed for certain environmental factors which include the size of the area where it’s being used and also the environmental situations it might have to encounter. And so cable assemblies are available in numerous sizes and shapes and are made to shield the internal wires and cables from friction, moisture, heat, compression, abrasion, and other problems.

So the difference between wire harnesses and cable assemblies is that they are used in different environments. Wire harness provide a cost-efficient solution for keeping the wires organized whereas the cable assemblies keep all the products secure in the extreme environments as well.

FAQ'S

What is the difference between a cable assembly and a wiring harness?

Cable harness conducts power and transmits information in a uniform way. Engineers and designers must explain and overcome electrical issues regularly, especially during the electronic product research and development stage to bring a product to the market successfully.

One of the most important part of this includes a challenge which has a custom design for each products electronic part and step by step cable harness manufacturing procedure to finish the assembly. In this step, designers select harness components and decide on other use specifications.

Cable assembly can be used for what kinds of applications?

Cable Assemblies are used with almost every other electrical system. Jayshree Instruments focuses on manufacturing high-quality cable assembly components in different industries like medical, telecommunications, industrial, military and others. The design capabilities are different depending on the kind of industry.

We can help you design the perfect set-up for any application as per your requirement. Our experienced and skilled engineers make sure to satisfy the all the complicated requirements of the clients with products which can be utilized for the long term. Jayshree Instruments also serves customized designs.

Why do cable assemblies require filters?

Cable assemblies consist of filters which can be easily overlooked for their simplicity. But actually filters provide numerous important support functions to the cable assembly.

Generally custom cable assembly needs using wires with a variety of diameters. Filters play a major role, by helping them maintain the round shape of the cable. It helps to keep uniform appearance and offers support as well.

Does Jayshree Instruments create a custom prototype for the required cable assembly?

Jayshree Instruments provides high-quality internal prototype PCB assembly services so that you may test your product before deciding to invest in its manufacture. Our primary area of competence is offering cutting-edge, dependable electronic manufacturing services. We are aware of how important prototyping services are.

We are an electrical contract manufacturer, thus we are familiar with the difficulties faced during the prototype stage. Our goal is to provide you with a complete electronic manufacturing solution and market-ready your product.