Introduction

Most of the time, people get confused between wire harnesses and cable assembly. This is so as the terms are generally interchangeable and both these products have quite similar basic functions. But both these products and their purpose are different from each other. Even the difference between wire and cable has to be understood. A wire can be defined as an insulated metallic conductor that is made up of copper, is flexible, and is used to transmit electric current in a circuit. A cable is a group or collection of wires that are braided together and appear like intertwined wires. Likewise, a cable assembly is a collection of cables organized within a single unit. The cable harness is an integrated and systematic collection of cables in an insulating material. The assembly helps to transmit electrical power.

Wire harness manufacturers have to keenly pay attention to the design review, assembly documentation, Bill of materials, production of the wire harness, and quality testing. Cable manufacturing encompasses designing and manufacturing cables, electrical wires, and conductors. One of the leading electronic manufacturing companies in Ahmedabad, Jayshree Instruments Private Limited provides a comprehensive range of cables and wires, it constantly keeps evolving based on the radical transformation in technology. The company is renowned to cater products as per the specifications of the clients.

Fast Charging Cables

In this technology-driven era, where everything is based on speed and time, the same applies to charging our phones and laptops too. One of the most important features that everyone looks out for while considering any technology is the fast charging component. But do note that not all products use a similar type of fast charging. Fast charging depends on voltage and amperage. To avail of the fast charging speed of any device, you should use a fast-charging cable and fast-charging power brick. Identifying fast charging cables can be tricky; you can check the amperage, thickness of the cables, description on cable, and buy from a reliable source. The main component for the fast charging cable is the cable assembly.

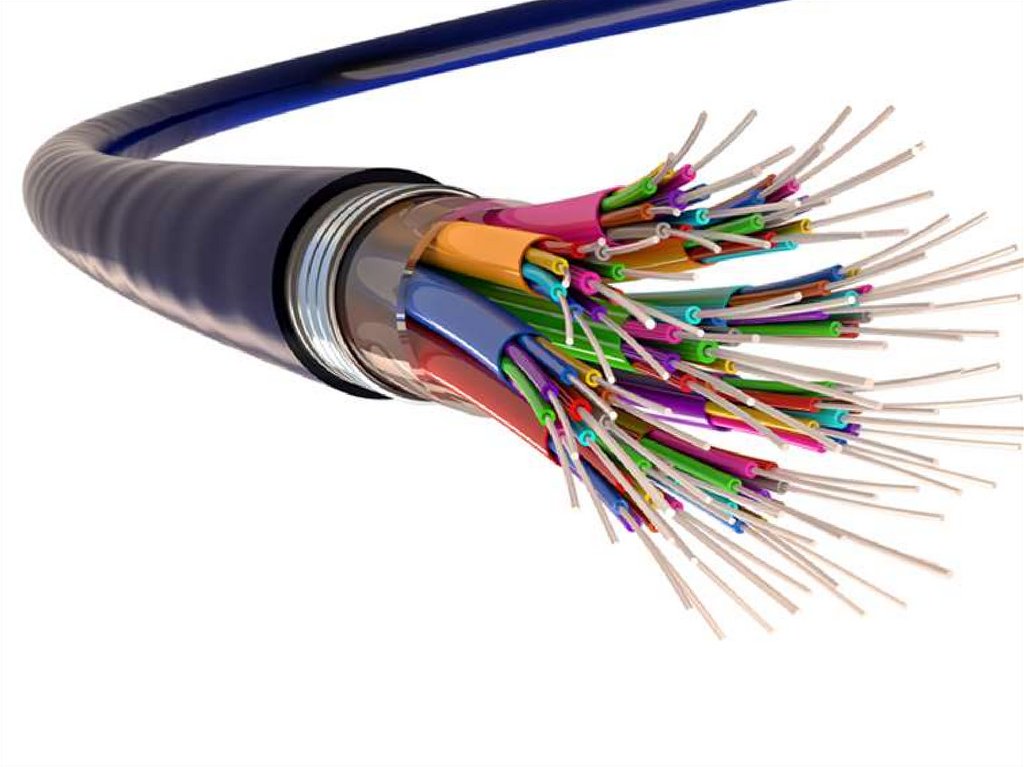

Fiber Optic Cables

Fiber optic technology or fiber cable is an efficient cable-based communication system. Fiber optic cable assemblies consist of a strong strand for support, optical fiber, and fiber optic cable connectors. Compared to copper wires that transmit data using electrical pulses, fiber optic assembly relies on the light pulse transmission that passes through the cable that delivers data at a faster rate. The most important point to consider during the fiber optic cable assembly process is to contemplate how to prepare the cable before termination. Fiber optic cables when compared to wired cables provide superior bandwidth and can transmit data over huge distances. Most of the world’s internet, telephone systems, and cable television are supported by fiber optic cables.

Insulated Wire and Cables

There is a range of wires and cables in the market, so do numerous wire and cable insulations. An insulated cable or wire consists of material that is non-conductive or that is resistant to an electric current. This material covers and protects the cable or wire inside. The cable needs to be insulated, as the electricity is a type of energy that may be fatal if it gets in direct contact with any human being. Insulation also helps to prevent the energy from scattering into the surroundings, thus conserving it. An insulated copper wire is generally used for the construction of inductors, transformers, speakers, motors, electromagnets, hard disk head actuators, and more. Several cable assembly manufacturers in India, provide multi-conductor cable assemblies that are wrapped with an insulation sheath.

Overmolded Cable Assemblies

A process in which either injection molding or insert molding is used to merge connectors and wires in a single piece is known as cable overmolding. This process requires the components of the cable assembly to be placed in a mold and then hot liquid plastic material is poured on it. Once it cools down, the final product will match the shape of the mold and will then be able to protect the connection of underlying connectors and wires. This is an ideal solution to seal the cable assemblies and their connectors.

Overmolded cable assemblies provide resilience and strength to the cable assembly. Jayshree Instruments Private Limited, in Gujarat, is amongst the leaders in the manufacturing and design of modern Overmolded cable assemblies. They discuss and guide their clients on when they should use the cable overmolding in their customized cable assembly design project to achieve the maximum benefit.

Custom Design Cable Assemblies

At a time when you feel that the standard cable assembly does not fit or suit your needs, it’s time to consider a custom design cable assembly. Custom design cable assemblies are engineered, designed, and manufactured precisely as per your requirements. By doing so, you will gain many benefits to your project. Custom cable assembly manufacturers will create exactly as per what you want the assembly to do. They would create as per your specific requirements, so you don’t have to worry about the cable run length, there would not be any extra cable, and the cable quality would not suffer as well. Custom cable harnesses are the best solutions for clients who belong to industries such as Automotive, Defense, Mining, Medical, General Electronics, and Telecommunications.

Hybrid Cabling and Encapsulation for Medical Applications

A cable in which numerous types and sizes of conductors are integrated into a single package is known as a hybrid cable. Hybrid cabling and encapsulation provide a cleaner look with a reduced diameter as well. Medical cable assemblies are used to connect laboratory and medical equipment and instruments. They are quite effective for cleaning and sterilization. They consist of separate cables that are strapped with connectors at one end into a single unit. Medical cables comply with regulatory standards and follow application-specific safety measurements. Medical cable harness assemblies are designed and produced as per the stringent requirements of the medical industry. They are made with approved components that match the desired high quality and performance standards. EKGs, ultrasound machines, other medical monitoring, and testing equipment are created with the help of wire harnesses and cable assemblies.

Flat Ribbon Cable Assemblies

Flat cable assemblies, planar cable assemblies, and ribbon cable assemblies all three names refer to the same distinctive type of cable assembly. Since the wires are arranged parallel to each other and are laid flat, the completed product is flat and wide and resembles a ribbon. This shape makes it quite flexible to fit in spaces where other cable assemblies may not be able to fit. Flat ribbon cable assemblies are used with CD drives, printers, computers, and other internal connections in electronic equipment and devices. Cable harness manufacturers in India based on the current trend in the market use state-of-the-art machinery to produce ribbon cable assemblies.

FAQs Regarding Cable Assembly Trends

- What is the growth rate of the global cable assembly market?

The growth of the global cable assembly market is estimated to have a value of around 149 billion dollars in the year 2019 and is expected to soar around 220 billion dollars by the year 2025. The growth at CAGR is around 6.7%. The factors that influence this growth are the increased demand from the aerospace industries, increase in the production of electric vehicles, and growth in the penetration of the internet across the world.

- What are the major products of a cable assembly in the industry?

The major cable assembly products in the industry are as below:

- Rectangular Assemblies

- Fiber Optic Assemblies

- Printed Circuit Board Assemblies

- Radio Frequency Assemblies

- Application or Custom Specific Assemblies

- Circular Assemblies

- What are the different types of cable assemblies?

The different types of cable assemblies are as below:

- Flat Ribbon Cable Assemblies

- Coaxial Cable Assemblies

- Military Grade Cable Assemblies

- Molded Cable Assemblies

- What materials are used in a wiring harness?

The materials that are used for the wiring harness are as below:

- Wires

- Cables

- Locks

- Terminals

- Outer coverings

- What is the difference between wire harnesses and cable assembly?

The difference between wire harness and cable assembly is majorly based on their applications. Some other differences between the two are indicated as below:

- A wire harness is best to be used indoors, whereas the cable assembly is suitable for outdoor usage.

- Cables are mostly used for industrial applications whereas wire harnesses are used for indoor electronics

- Cable assembly looks and functions like a single thick wire

- The cost of a wire harness is low as compared to the cost of cable assembly

Recent Comments